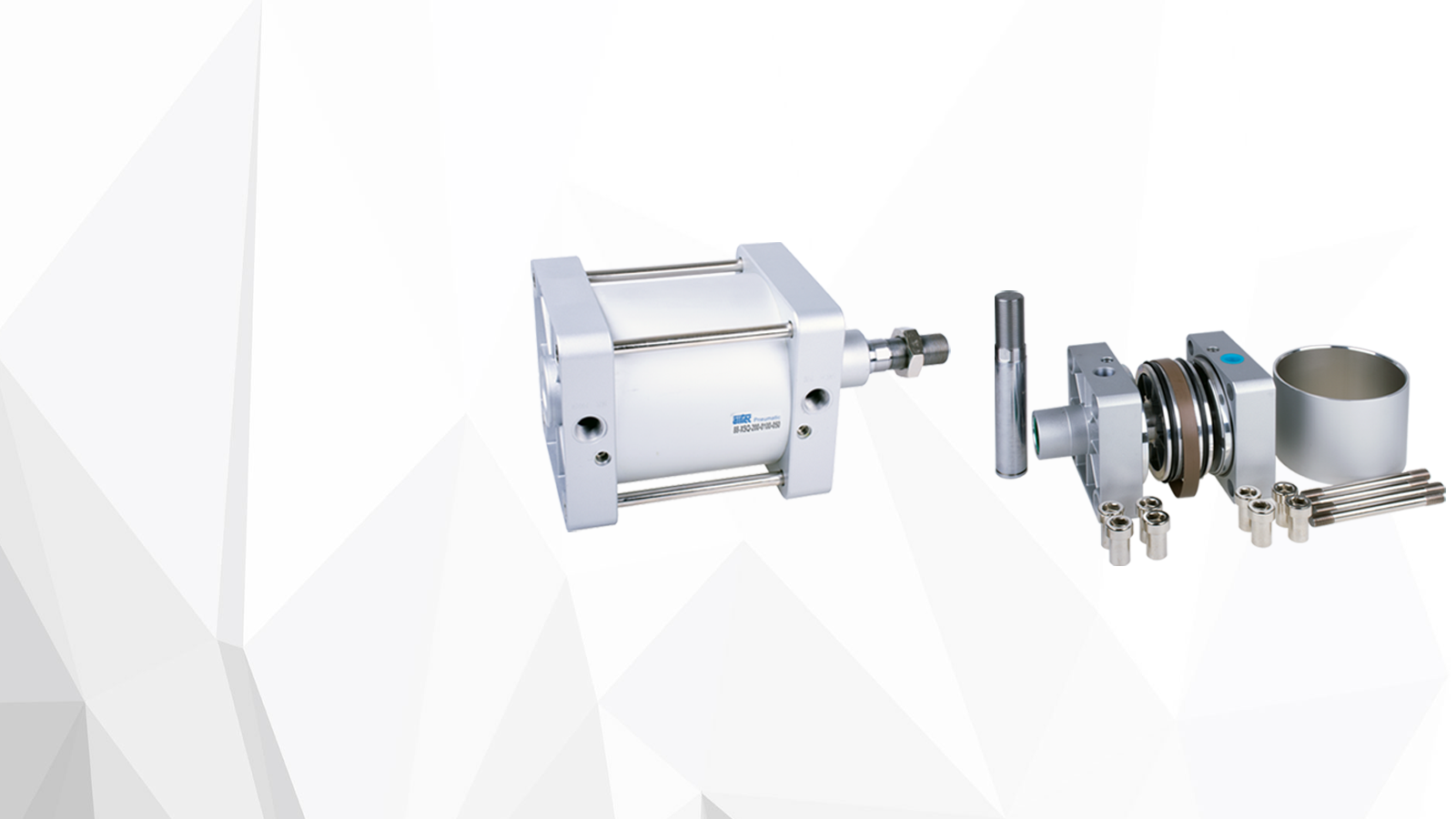

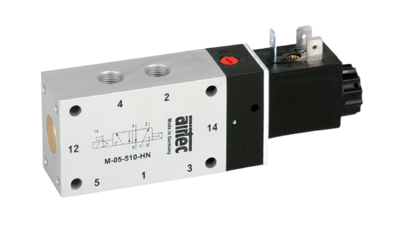

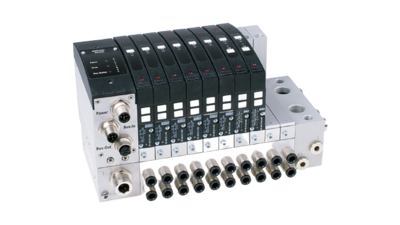

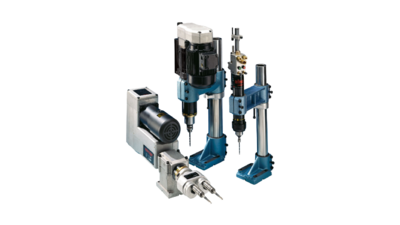

Pneumatic control technology for the highest demands

In addition to a broad standard programme, AIRTEC develops individual pneumatic systems: Experienced engineers enable customers to produce more efficiently, better and faster with clever solutions. AIRTEC calls this "Solutions in Motion" - solutions in motion

Make an enquiry now!

At AIRTEC, good service is a top priority.

That is why we are happy to advise you personally and competently.

Submit your enquiry here and we will get back to you as soon as possible.